Although not as celebrated as many other scientific inventions, the smoothing iron has its own rich history of development stretching all the way from 400 B.C. to the present. The electric iron has been around since the 1880s, but as is the case with many modern inventions, it has its roots in ancient history.

Circa 400 B.C., Greeks would heat a round bar – known as a goffering iron – and use it to produce pleats on robes. The ancient Romans used devices more similar to the irons of today. One was a level metal paddle in which the user would beat the clothes in the hope the pounding would remove the wrinkles. The ancient Chinese used a scoop that was heated with hot coal or sand and would rub it over clothing to smooth wrinkles.

What modern customers would identify as an iron first appeared in Europe in the 1300s. The flatiron, as it was called, was simply a smooth piece of metal affixed to a handle. The iron would be heated over flames until sufficiently hot, at which time it would be picked up with an insulated glove. A layer of cloth would cover the article of clothing to prevent soot from the iron from staining the finished garment. Once the flatiron cooled, it would be reheated and the process repeated. Besides smoothing wrinkles, ironing served another important function, killing germs in clothing and reducing mildew.

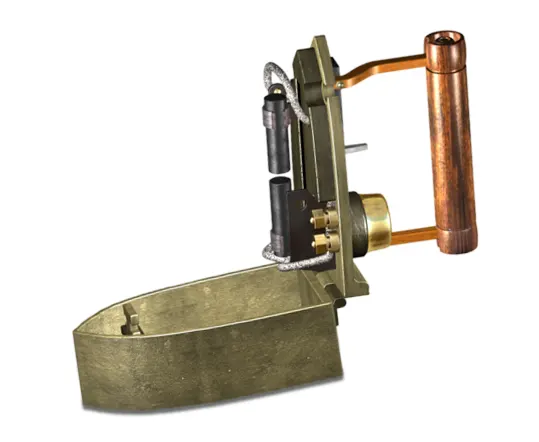

It took about two centuries for the next significant improvement to the flatiron. The “box iron” was composed of a flat-bottom box and a handle. Hot coals, bricks or other heating elements were placed inside. Such a design removed the need for a protective layer of clothing between the garment and iron because the iron retained a clean surface. The box iron remained the standard for several hundred years.

Metal technology began developing in the 1800s, hastening the evolution of the smoothing iron. Flatirons could be heated atop cast iron stoves, making the job much easier and cleaner than fire. By 1870, wooden handles were used, preventing users from receiving burns, as wood does not retain heat in the manner of iron.

Gas irons were patented in the 1870s, making the devices even easier to use. A gas line would carry fuel to the appliance, which contained a burner to provide the heat. These irons were much lighter than their predecessors, which often weighed up to 15 pounds.

The invention of the electric iron coincided with the widespread electrification of American homes in the 1880s. In 1882, Henry W. Seeley of New York City received a patent for the electric flatiron. His model had built-in coils and was heated on a rack. The problem was that it took a long time to heat and cooled rapidly once in use.

Perhaps the biggest breakthrough in smoothing-iron technology occurred early in the 20th century, when irons were made with electric cords. The development helped solve the centuries-old necessity of constantly reheating the iron. Improvements also were made to the sole plate (bottom) of the iron and by the 1920s, many irons came equipped with thermostats to control the level of heat.

In the mid-1920s, the Eldec Company unveiled the steam iron, which facilitated the pressing of dry material. Up to that point, users had to sprinkle water on the fabric. The steam irons funneled water vapor from a receptacle to small holes on the sole plate.

Other improvements in the following decades included the development of an aluminum sole plate that would not rust. In the 1950s, irons capable of both wet and dry operation were introduced, and in 1995, most sole plates had nonstick coating. By this time, about 14 million irons were sold annually in the U.S.

Irons will have a place in department stores for as long as consumers take pride in the smooth appearance of their clothing. As for their future, there is still room for improvement on the sole plate. Improved coatings will make it less susceptible to scratches from zippers or buttons on garments. Devices that allow for better regulation of temperature and steam are also expected to evolve.